Access control systems & kits (1,016)

High protective level: IP65 and IK08 Slim and flexible design with metal 3,000 fingerprints, 10,000 cards and 100,000 events storage Built-in card reader for M1 card Supports operation by mobile App (Hik-Connect) Supports AP configuration, configuration via PC web and mobile web are available Supports multiple authentication types: card, fingerprint, PIN, and bluetooth

Add to Compare

2.4-inch LCD screen to display time, date, week, and attendance information TCP/IP communication 1:N mode accurate and fast fingerprint recognition (recognition duration < 1 s) Max. 1000 users, Max. 1000 fingerprints, and Max. 100,000 events records Stand-alone operation (supports adding persons, and fingerprints locally) Downloads attendance reports by USB flash drive Up to 32 normal shifts, 32 man-hour shifts, and 32 attendance holiday schedules can be configured Supports 6 attendance status, including check in, check out, break in, break out, overtime in, overtime out Generates reports automatically Supports multiple languages: English, Vietnamese, Brazilian Portuguese, Spanish, French, Italian, Arabic, Thai, Turkish, Indonesian, and Ukrainian Supports ISAPI protocol and ISUP 5.0 protocol

Add to Compare

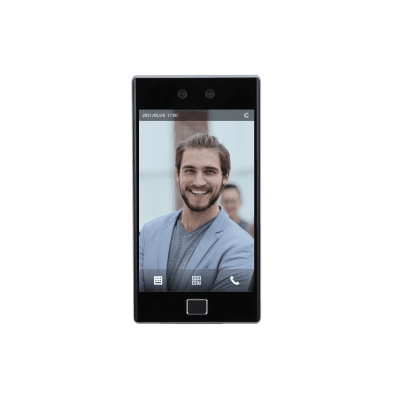

DS-K1T500S is a kind of video access control terminal, which is equipped with HD camera(2 MP/1080p). It supports multiple advanced technologies including face detection, smart card recognition, two-way audio, remote live view, picture capture, video recording through NVR, and so on.

Add to Compare

2.4-inch LCD screen to display time, date, week, and attendance information TCP/IP communication 1:N mode accurate and fast fingerprint recognition (recognition duration < 1 s) Max. 1000 users, Max. 1000 fingerprints, and Max. 100,000 events records Stand-alone operation (supports adding persons, and fingerprints locally) Downloads attendance reports by USB flash drive Up to 32 normal shifts, 32 man-hour shifts, and 32 attendance holiday schedules can be configured Supports 6 attendance status, including check in, check out, break in, break out, overtime in, overtime out Generates reports automatically Supports multiple languages: English, Vietnamese, Brazilian Portuguese, Spanish, French, Italian, Arabic, Thai, Turkish, Indonesian, and Ukrainian Supports ISAPI protocol and ISUP 5.0 protocol

Add to Compare

All-in-one solution for access control, complete with an ACM™ Appliance, LifeSafety Power Enclosure, Mercury Controller and Sub-Panels, RP40 Readers, and 100 pre-programmed HID® Cards. No card programming information required Pre-configured settings available

Add to Compare

Fingerprint Time Attandence Terminal, Built-in EM card reading module 3,000 fingerprints, 3,000 cards and 100,000 events storage Communication via TCP/TP and Wi-Fi Power supply:5 VDC/1 A Back-up battery supported ISUP5.0, ISAPI

Add to Compare

Integrated management of access control and the time and attendance functions 3,000 fingerprints, 3,000 cards and 100,000 events storage Built-in card reader for EM card Communication via TCP/TP and Wi-Fi RS-485, wiegand interface Alarm input and output interface ISUP5.0, ISAPI

Add to Compare

Fingerprint Time Attandence Terminal, Built-in Mifare card reading module 3,000 fingerprints, 3,000 cards and 100,000 events storage Communication via TCP/TP and Wi-Fi Power supply:5 VDC/1 A Back-up battery supported ISUP5.0, ISAPI

Add to Compare

Fingerprint Time Attandence Terminal LCD display screen 3,000 fingerprints, 3,000 cards and 100,000 events storage Communication via TCP/TP and Wi-Fi Back-up battery supported EHome for public network communication Multiple time attendance status European power supply adaptor included (please mark for other standards when you order)

Add to Compare

All-in-one solution for access control, complete with an ACM™ Appliance, LifeSafety Power Enclosure, Mercury Controller and Sub-Panels, RP40 Readers, and 100 pre-programmed HID® Cards. No card programming information required Pre-configured settings available

Add to Compare

Fingerprint Time Attandence Terminal LCD display screen 3,000 fingerprints, 3,000 cards and 100,000 events storage Communication via TCP/TP and Wi-Fi Back-up battery supported EHome for public network communication Multiple time attendance status European power supply adaptor included (please mark for other standards when you order)

Add to Compare

All-in-one solution for access control, complete with an ACM™ Appliance, LifeSafety Power Enclosure, Mercury Controller and Sub-Panels, RP40 Readers, and 100 pre-programmed HID® Cards. No card programming information required Pre-configured settings available

Add to Compare

Integrated management of access control and the time and attendance functions 3,000 fingerprints and 100,000 events storage Built-in card reader for Mifare1 card Communication via TCP/TP and Wi-Fi RS-485, wiegand interface Alarm input and output interface ISUP5.0, ISAPI

Add to Compare

Aperio® Offline access control doors now allow access control system manufacturers (OEMs) and system integrators to offer even more favourably priced solutions, thus creating a competitive advantage for themselves. All they need to do is integrate Aperio® components into their system, an easy task. Aperio® Offline is particularly suitable for doors which cannot be wired, are used very little or are a distance away from other doors. Very easy to install, an Aperio® Offline cylinder or escutcheon is mounted onto the door and then integrated into the access control system. Access authorisations are saved onto existing RFID user cards or transponders. Doors are all managed using the same access control system, whether they feature Aperio® Offline or Online. Users receive new or modified access authorisations from a central point. One special feature in Aperio® Offline is its status message capability used to indicate low battery status or a jammed lock and transmit other door signals to the access control system via the cards or transponders. This allows system maintenance to rectify faults or replace batteries within a short space of time. Lost user cards and transponders can be cancelled by placing them on a blacklist or become automatically invalid after a specific period of time. Able to support up to 16 time schedules, Aperio® Offline also offers a permanently open mode (office mode) and door status change (toggle mode). For customers or end-users, the greatest advantage lies in the fact that they can now choose the right access control system for every door scenario. Regardless of whether the door is Aperio® Online or Offline, both can be administered using the same access control system. Aperio® Offline cylinders or escutcheons can also be easily used for Aperio® Online if operators wish to integrate a door into an online system at a later date. In such a case, the door is incorporated into the access control system via a wireless communications hub, thus providing a favourably priced, non-wired, online solution.

Add to Compare

8" LCD with a resolution of 1280 × 800. 2-MP CMOS dual-lens camera. Supports 100,000 users (including up to 50 administrators), 100,000 faces, 500,000 cards, 100,000 passwords, 10,000 fingerprints, and 300,000 records. Multiple unlock methods including face, IC card, password, fingerprint and QR code. You can configure scheduled unlock methods, or com bine them to create your own personal unlock methods. Recognizes faces 0.3 m to 3 m away (0.98 ft-9.84 ft), and is suitable for recognition of people with a height of 0.9 m to 2.4 m (2.95 ft–94.49 ft). Adopts deep learning face recognition algorithms to accurately rec ognize more than 360 key points of a target's face, offers contactless passage and performs face recognition at 0.2 sec/person. Supports face mask detection. Displays video and image advertisements. Recognizes up to 6 human faces at the same time. Supports person management on the webpage, including adding, deleting and editing persons. Compatible with multiple platforms such as DSS Professional, SmartPSS Lite and DMSS.

Add to Compare

7" LCD with a resolution of 600 × 1024. 2-MP dual-lens CMOS camera. Supports 50,000 users, 50,000 faces, 50,000 passwords, 100,000 cards, 50 administrators, and 300,000 records. Multiple unlock methods including face, IC card, password and QR code. Recognizes faces 0.3 m to 3.0 m away (0.98 ft–9.84 ft), and detects persons between the height of 0.9 m and 2.4 m (2.95 ft–7.87 ft). Powered by the face recognition deep learning algorithm, the device can accurately locate over 360 key points on the face of a target. Faces can be recognized within 0.2 seconds, without need for the person to touch the device. Features face mask detection and safety helmet detection. Plays advertisements in video and image format. Supports extension modules for fingerprint, QR code and and fingerprint + QR code. Recognizes up to 6 faces at the same time.

Add to Compare

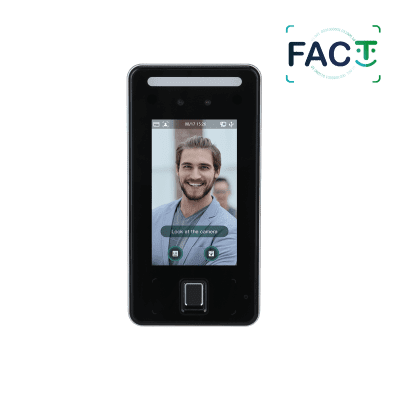

4.3-inch LCD touch screen; resolution 480 × 272 2MP wide-angle dual lens camera; support DWDR, white light fill light and IR fill light Support face, card, password ,fingerprint unlock and unlock through their combinations; support unlock by period User data can be stored at the access controller; can hold 6000 face images and work without network Face-camera distance: 0.3 m-1.5 m Face verification accuracy 99.5%; face comparison speed 0.3s per person; low false recognition rate; support liveness detection

Add to Compare

Save money & space - Save up to 70% compared to the cost of buying a locker for each employee. Maintenance costs are low as there’s no batteries to change or keys to supply, and low power consumption means low energy costs. High security levels - It’s the only locker system to read encrypted customer-specific data, so only your organisation’s cards can operate your lockers and cabinets. Every lock has a tamper alarm and you can see who opened each one and when. Easy to manage - You manage all lockers and storage cabinets centrally via a smartphone-friendly web interface. You always have an up-to-date overview on their status, and there are no keys to issue, track or replace. Easy to use - People use one access card for everything. They can open lockers and cabinets quickly by holding their card to the lock, and then lock it the same way. There are no complex instructions or queuing at terminals. Always in control - Even if your network fails or there’s a power blackout, all lockers and cabinets can still be used and remain secure. So you stay in control of which people can access each one and at what times. Integrated - Use a single card to access lockers, your building and the car park.

Add to Compare

High protective level: IP65 and IK08 Slim and flexible design with metal 10,000 cards and 100,000 events storage Built-in card reader for M1 card Supports operation by mobile App (Hik-Connect) Configuration via PC web and mobile web are available Supports multiple authentication types: card, PIN

Add to Compare

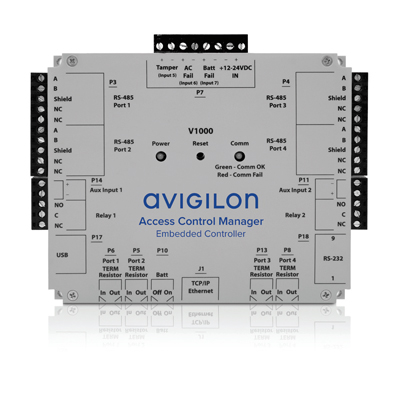

The Access Control Manager (ACM) system is an IT-friendly Physical Access Control System (PACS) from Avigilon for enterprise-class installations. It’s a complete system that is designed to keep your focus on securing your people, property and assets, and maximizing your time by helping you respond immediately to alerts wherever you are. The ACM™ system is a browser-based solution that can integrate with existing IT/HR systems, minimizing the need for duplicate data entry. It comes with a full set of standard features that not only help to maximize your time, but will reliably safeguard your information.

Add to Compare

Johnson Controls offers more options for customers to protect their people, property and assets. The P2000 security management system is now compatible with Authentic Mercury™ access control hardware from Mercury Security Corporation®, the world’s largest provider of open platform access products. The P2000 system integrates technologies including video surveillance, fire alarms and building management systems to provide customers with a single view of their building’s security and operational performance. “The upgraded P2000 enhances information technology to improve real-time system performance, reliability and system administration. A new archive support server stores data for up to 30 years and generates scheduled reports.

Add to Compare

High protective level: IP65 and IK08 Slim and flexible design with metal 3,000 fingerprints, 10,000 cards and 100,000 events storage Built-in card reader for EM card Supports operation by mobile App (Hik-Connect) Supports AP configuration, configuration via PC web and mobile web are available Supports multiple authentication types: card, fingerprint, PIN, and bluetooth

Add to Compare

Traka, a division of ASSA ABLOY presents the Traka Touch L Series intelligent touch screen key management system. Traka Touch is a standalone key management solution that operates independently of a company’s IT system via an embedded Windows software and SQL Server database. No server is required to maintain its database. The system is managed via the full colour 7-inch multi-language touch screen on the front panel, from the initial administrative setup of users and keys to the management of day-to-day user access. As with conventional Traka systems the Touch gives the administrator control over the access levels for each particular user. To gain access to keys, users must identify themselves using a PIN code, swipe card or biometric recognition. LEDs indicate which keys a user can and can’t take when they access the cabinet. The Traka Touch provides a real time audit of all key transactions and the unit’s solid state memory can store up to 250,000 events. Administrators can view a report of all key usage and search for a key that is “out of system” via the touch screen. “The new Traka Touch is a secure, cost-effective means of ensuring that only authorised individuals have access to keys, while making them readily available to authorised users 24/7. It is not always feasible for organisations to allow access to IT infrastructures and networks and Traka Touch addresses this” said Robert Smith, Managing Director, Traka plc.

Add to Compare

One size does not fit all when it comes to managing a facility's access rights. With SMARTair™ from TESA, security managers have a choice between 4 levels of access control, each tailored to the needs of different doors and premises. And you don't need to choose one: all of them can work together in the same organisation, providing exactly the appropriate rights management solution for each door—online or offline, high or medium security. SMARTair™ Stand-Alone is suited for smaller premises and low-traffic doors. Facility managers update access rights at the door using the supplied programming card. No access control software is needed. SMARTair™ Offline provides an extra layer of security. In addition to SMARTair™ Stand-Alone features, access rights can be scheduled and it's easy to generate a manual audit trail for any door in the facility. The SMARTair™ Update on Card option adds more automated access rights management, and is suited to buildings with more doors and higher footfall. Access rights are managed via a wall updater. Facility managers can update access directly via user cards, schedule access rights when needed, and generate automatic audit trails with the easy-to-use system management software. SMARTair™ Wireless Online provides the maximum level of system control for large, busy and high-security doors or buildings. A network of wireless hubs links doors to the company's access control system. It's easy for security managers to update or deny access rights wirelessly, or to generate real-time audit trails for any lock in the organisation. Moreover, system managers can open doors remotely via a web browser or mobile app. Facility managers can pick 1, 2, or even all 4, of these SMARTair™ solutions to fine tune their organisation's access rights management. And SMARTair™ gives facilities managers the power to manage access to more than just doors. As well as electronic cylinders, escutcheons, locks, and wall readers, SMARTair™ provides locks for cabinets, lifts, vending machines, and lockers. With SMARTair™ from TESA, it is simple to manage the rights of every lock within one single, secure access system.

Add to Compare

High protective level: IP65 and IK08 Slim and flexible design with metal 10,000 cards and 100,000 events storage Built-in card reader for M1 card Supports operation by mobile App (Hik-Connect) Supports AP configuration, configuration via PC web and mobile web are available Supports multiple authentication types: card, PIN, and bluetooth

Add to Compare

High protective level: IP65 and IK08 Slim and flexible design with metal 10,000 cards and 100,000 events storage Built-in card reader for EM card Supports operation by mobile App (Hik-Connect) Supports AP configuration, configuration via PC web and mobile web are available Supports multiple authentication types: card, PIN, and bluetooth

Add to Compare

High protective level: IP65 and IK08 Slim and flexible design with metal 10,000 cards and 100,000 events storage Built-in card reader for EM card Supports operation by mobile App (Hik-Connect) Configuration via PC web and mobile web are available Supports multiple authentication types: card, PIN

Add to Compare

When it comes to key management Traka Touch makes your life easier. It gives you an intelligent ‘out of the box’ key management solution which operates entirely independently of your IT systems. Everything is managed via the touch screen on the front panel, from the initial administrative set up of users and keys, right through to the day to day user access.

Add to Compare

Traka’s rack manager is an intelligent solution that allows you to restrict rack access to authorised users only. Furthermore, it allows you to maintain a full audit of who has accessed which rack, and when. The rack manager can be fully integrated with your current access control system. The interface to the system is a 7 inch touch sensitive pod, which uses the latest embedded processing technology. With the rack manager all access to data racks is managed via the touch screen pod. Each authorised user identifies themself at the pod (via Smart card, biometrics or PIN) and selects the rack they wish to access.

Add to Compare

When it comes to industrial Internet-of-Things and Industry 4.0 issues, we usually think about the investment in automated equipment as well as the application of software systems such as MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning). But enterprise leaders do well to note that smart manufacturing is more than that. We see today’s manufacturers facing three major challenges: Personnel Management – While people, or labor, remains the essential element of the production process, their output relies on finer management; Visibility across the process – Automation equipment and software systems need more timely alerts and improved incident handling protocols, as well as forward-looking insights, to guarantee operational stability; and Lean Management for Boosted Productivity – In environments as complex as manufacturing plants, lean management regarding factors of production such as office park vehicle traffic, dock management, and information sharing, are also important in boosting productivity. The good news for manufacturers is that Hikvision’s intelligent manufacturing solutions can help with all of these critical management requirements – and more. The Hikvision solution leverages AIoT technology to shift offline data online where it can be monitored and utilized. AI and intuitive visualization technology also allows managers to monitor the site, production, and operational processes, and to respond in real time in the event of an issue – helping to drive efficiency and productivity. Managing personnel more efficiently Manufacturing parks have significant personnel management requirements, with large teams arriving on site and accessing specific areas for their work all day long – creating complex logistics, access management, security, and health and safety requirements. Hikvision’s Quick Access Solution, enabled by Hikvision MinMoe face-recognition terminals, gives employees touch-free access to manufacturing sites, covering the main entrance, the floor, offices, exits, production areas, EPA areas (ESDPA – Electrostatic Discharge Protected Area), and more. The technology provides “non-stop” access to ensure that employees can enter the site quickly, even during peak times – such as morning and evening rush hours or in bad weather. The solution safeguards plant safety with precise access management. For example, only authorized staff can access specific areas of the site, which helps to boost security. For visitors,the solution provides full-journey online management, which increases convenience. With no blind spots for security, the solution also protects the park against theft and vandalism. Another benefit of the Quick Access Solution is that it turns physical footprints into digital records for accurate time &attendance management. Based on a manufacturer’s choice of verification and identification methods – from face recognition to fingerprint readers, cards or PIN codes – employees can be identified and attendance reports and work records can be generated automatically. This ensures that the HR department can support employees effectively, optimize time & attendance management, and maximize accuracy for payroll, overtime, and compensation in general. The Quick Access Solution can also be used to manage in-park facilities – such as employees visiting the cafeteria, for example, as well as facilitating zero-contact payment. Maximizing visibility for production and operations Organizations with large-scale production environments often experience information silos, making it difficult to detect and respond to incidents in real time or to make changes that actually increase efficiency. Hikvision’s AR Live Interaction Solution offers a solution to these challenges by providing full visibility of large-scale production processes. The solution uses Augmented-Reality (AR) cameras and easy-to-use location capabilities to create a live map of a site, giving managers a bird's-eye view. The system, which integrates seamlessly with other industry control systems, presents production information and site images on a four-screen display. Some of the key features of the AR Live Interaction Solution include remote inspections, alarm handling, automated information collection and analyses, predictive maintenance for equipment, and performance evaluations. The system also detects defects in equipment and human errors to minimize downtime, mitigate safety risks, and provide insights for better decision making. With the AR Live Solution, manufacturers can also place visualized displays in the workshop, adding an extra layer of visibility for assets and production processes. Visual images can be used to send safety reminders to employees, to facilitate communications between teams, and to improve work supervision and collaboration for improved efficiency. Optimizing facilities and traffic management For all manufacturing parks, the ability to manage the flow of vehicles efficiently and safely is of paramount importance. This requires real-time visibility of driving and parking on site, as well as monitoring of loading and unloading, scheduling and dispatching, and security across all areas of the site. Hikvision’s Park Traffic Management Solution standardizes on-site vehicle flow to help park managers embrace innovation and increase productivity. The solution is powered by AIoT technologies, including cameras with tailored algorithms, auto-triggered radar, management software, LED displays, and more. These technologies all come together to help operators create more manageable park environments, and to improve vehicle and resource allocations for optimal efficiency. Speed measurement cameras and LED Screen with real-time speed and ANPR displays help to regulate driving practices at a worksite. This helps to reduce accidents caused by speeding, reverse driving, driving out of lane boundaries, illegal lane changing, and more. Meanwhile, illegal parking cameras detect vehicles that have stopped in prohibited areas that could cause accidents or injuries. All video images and alarms are received and displayed at a command center managed via HikCentral Professional software. Here, displays show real-time information such as vehicle license plate numbers and speed, enabling operators take prompt action in case of an emergency. By creating a safer, more orderly park environment, site operators can help incoming drivers locate the right loading docks and warehouses more quickly and easily. Managers also find it easier to stay up-to-date with vehicle statuses, to control traffic, allocate resources, and respond to emergencies. In the end, this all leads up to racially improved productivity and more efficient operations. Find out how, with Hikvision Hikvision’s cutting-edge technologies are helping manufacturers to boost their management capabilities around the world, every day, leading to greater efficiency, improved productivity, and site security and safety.

Add to Compare

Traka Ltd RFID Lockers use Traka software. They are run in 'advanced locker administration' mode and are controlled from a local Windows PC or run centrally from a networked server. Each device is uniquely RFID tagged so that it is managed, controlled and individually accounted through the Traka software. RFID lockers ensure secure storage so that only authorised, competent and trained staff can gain access to specific assets, partly for security and compliance reasons, but most importantly for control purposes.

Add to Compare

Traka Alcolock is a key management system with alcohol testing. After opening the Traka key cabinet using PIN, access card or biometrics reader the user then selects the required key to a particular vehicle or piece of equipment. However, before the key is released the system display requests the user to blow into the Alcolock.A five second blow and the system will confirm a Pass or a Fail. Only if Passed will the key be released. Should a user fail the breath test, then the key will be locked in place. The Fail will be logged in the Traka database together with the user's name. The user will then need to inform their supervisor or line manager.

Add to Compare

Key features: 100% browser based application factory installed by Avigilon Simplified programming and navigation IP enabled controller Supports offline mode Removable terminal blocks for easy installation Plastic enclosure protects vital components HID VertX V200 input control interface and V300 output control interface supported Four Door Reader Kit includes: One AC-LSP-4DR-HID-LCK LifeSafety Power four door HID dual voltage integrated power system One Avigilon AC-HID-ACMEC V1000 ACM Embedded Controller Two AC-HID-VERTX-V100 HID VertX V100 reader interface modules Four AC-HID-READ-ICLASS-SE-R10-AVG HID iCLASS SE R10 card readers 100 AC-HID-CARD-ICLASS-SE-3000-AVG iCLASS SE contactless smart card, 2k bit with two application areas

Add to Compare

Traka Bespoke lockers offers a range of standard key management cabinets and intelligent locker solutions, there are almost certainly, occasions when the 'one size fits all' approach is not applicable. Traka is able to create intelligent lockers in almost any combination of shape or size to suit your specific requirements. It is managed through the same Traka software as key management cabinets to enable the full range of access control, auditing, and management reporting. It can be supplied with in-built charging capability if required, or if preferred, with a separate charging bank for batteries in a lower locker compartment.

Add to Compare

Traka DockSafe safety management solution is a unique and easily installed drive off prevention system designed to stop vehicles prematurely leaving the Goods Out bays of a busy distribution centre – historically the source of many serious incidents within the industry each year. It can only be operated by an authorised driver and an audit trail is created which records the drivers ID and the time the lock was activated and de-activated. All of this is achievable as the memory chip within the iFob has a unique serial number, which is assigned to an individual driver. The Traka iFob allows authorised users to access the Salvo Susie lock.

Add to Compare

DSX-1042PKG intelligent 2 door package. Includes one 1040E Enclosure, one 1042 Controller, one 1040CDM Communication Distribution Module, and one 1040PDP Power Distribution Panel. Up to three additional Controllers can be added to this package. Any combination of 1042, 1043, and 1044 Controllers can be used.

Add to Compare